Shakedown problems

Posted: 14 Aug 2022 21:28

So, I managed to repair the lower front wings where I had cut away to gain access to the inner sills and have now repainted to satin black which is near to how they were when I bought the car and it's looking pretty good now - not perfect but pretty good so far.

I've covered about 15 miles so far into the shakedown period and am suffering what I think is possible fueling issues. I stripped, cleaned and re-assembled the carbs when I rebuilt the engine but only replaced gaskets and seals and have now balanced and adjusted them to the best of my abilities so am now at a process of elimination to cure the rough running and what I think feels like part fuel starvation which has suddenly manifested itself.

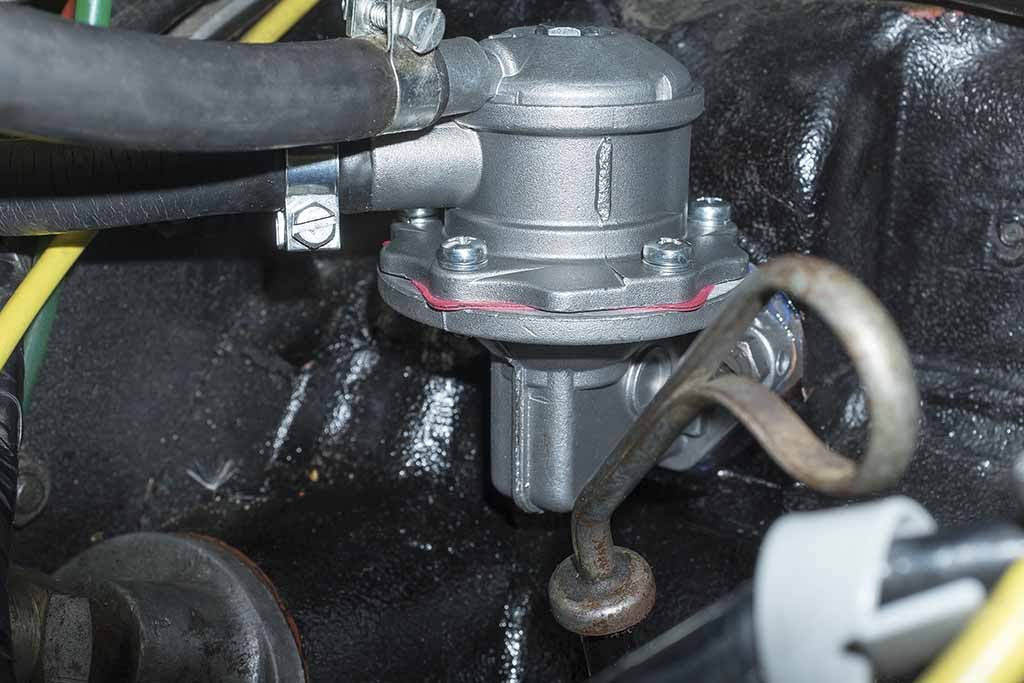

So far, I've checked the fuel supply up to the fuel pump and it's clean and clear with a good flow. I took the top off the fuel pump and the filter inside is pretty much spotless but as it's the original pump from when the car was built I'm wondering as to whether or not it's functioning properly. I had purchased a replacement pump a few months back but didn't get round to fitting it, but after trying to get it to fit I'm wondering if it is the correct pump ?

It will fit and bolt into position if I re-use the tufnol spacer, but it is decidedly 'clattery' when starting the engine and after a minute or less the engine cuts out, presumably when the float bowls have emptied, so I don't even know if it's pumping fuel when fited with the spacer. I don't think it's in the right position when fitted with the spacer but it won't fit without it - I can't get the bolts to locate as the operating lever fouls against the cutout in the block and holds the pump flange in the wrong position. Anybody know if this pump (top) should fit a 1980 dhc ? I've a feeling that it's maybe for an earlier car but did they even have two different pumps during the production lifespan ?

Original pump and spacer at the bottom of the pic...

I've covered about 15 miles so far into the shakedown period and am suffering what I think is possible fueling issues. I stripped, cleaned and re-assembled the carbs when I rebuilt the engine but only replaced gaskets and seals and have now balanced and adjusted them to the best of my abilities so am now at a process of elimination to cure the rough running and what I think feels like part fuel starvation which has suddenly manifested itself.

So far, I've checked the fuel supply up to the fuel pump and it's clean and clear with a good flow. I took the top off the fuel pump and the filter inside is pretty much spotless but as it's the original pump from when the car was built I'm wondering as to whether or not it's functioning properly. I had purchased a replacement pump a few months back but didn't get round to fitting it, but after trying to get it to fit I'm wondering if it is the correct pump ?

It will fit and bolt into position if I re-use the tufnol spacer, but it is decidedly 'clattery' when starting the engine and after a minute or less the engine cuts out, presumably when the float bowls have emptied, so I don't even know if it's pumping fuel when fited with the spacer. I don't think it's in the right position when fitted with the spacer but it won't fit without it - I can't get the bolts to locate as the operating lever fouls against the cutout in the block and holds the pump flange in the wrong position. Anybody know if this pump (top) should fit a 1980 dhc ? I've a feeling that it's maybe for an earlier car but did they even have two different pumps during the production lifespan ?

Original pump and spacer at the bottom of the pic...